Heatpower

Fast responding thermal energy systems

Reference projects

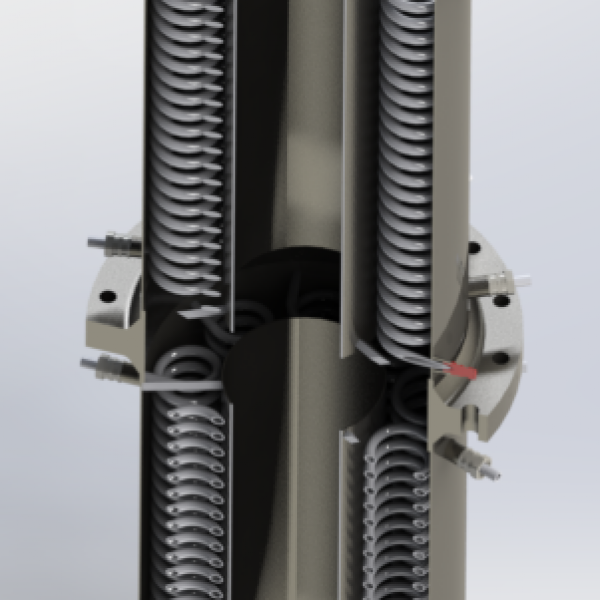

Metal fueled once through boiler system

80kW Once Through Boiler (OTB) fired by iron combusted flue gasses (<50um) with temperatures up to 600C. Water to saturated steam generation by use of forced convection boiler principle. Dry saturated steam generation up to 150C at 3.5barg, suitable for industrial low pressure steam processes.

Used as a proof of principle annex research setup and part of the 100kW Metallot iron combustion system. The delivered subsystem consist out of a modular stacked boiler skid with a complementary process skid, equipped with a vessel, pump, pressure control valve and corresponding pressure safety equipment. The control cabinet is carried out with a data acquisition and control system and is operational via a touchscreen control panel.

This project is funded by:

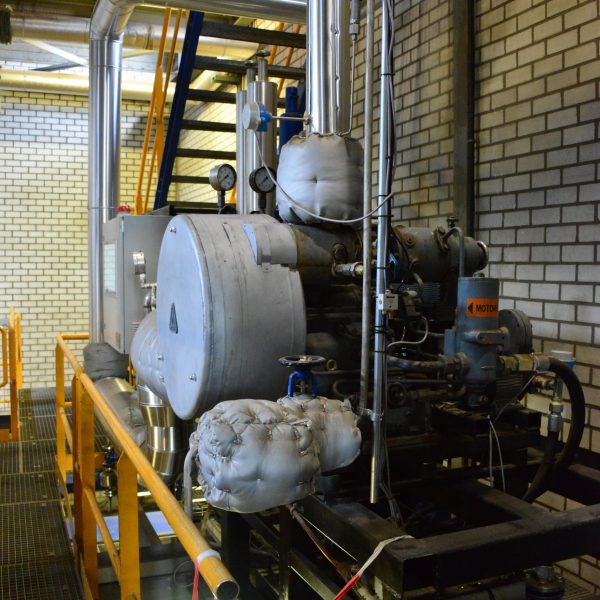

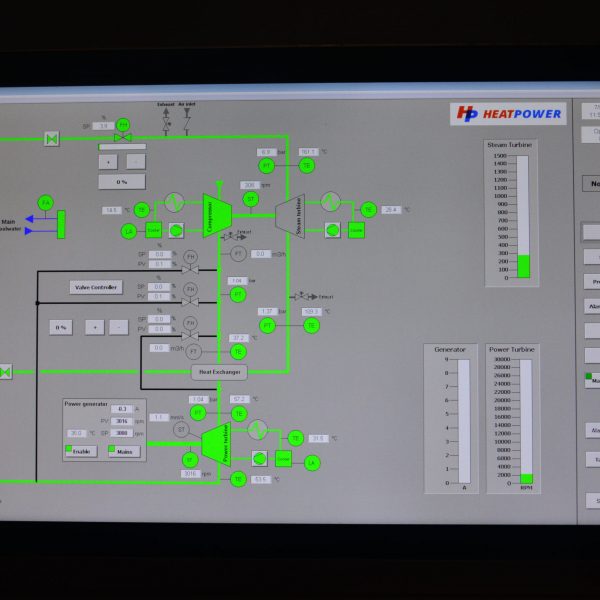

5kWe industrial rankine compression gasturbine (RCG)

A 5kWe industrial prototype of the Rankine Compression Gasturbine (RCG) has been successfully integrated into the production process of a wood milling plant in the province of Brabant. At the site, the RCG is fed with residual heat from the biomass oven of the factory. While the steam output of the RCG is used for wood drying, electrical peak shaving capabilities have been demonstrated and the generated electricity is used on site. While industrial feasibility is proven, focus is laid on the automation of the industrial prototype and the compliance with safety regulations. This project has been executed with financial support from the European Union

This project was funded with financial help of the European Union

Drain water thickener thermal cleaning plant

Design of a 5000L/hr

drain water thickener. Drainwater is a common residual product in a variety of

thermal cleaning processes. Discharge of drainwater is cost intensive and

therefore volumetric reduction (e.q. thickening) of drainwater is desired to

reduce discharge costs. Heat Power B.V. has designed and fabricated a small

test setup that is able to thicken the drainwater of a thermal cleaning plant,

by use of the factory’s excess heat. The system makes use of a Once

Through Boiler heat exchanger where saturated

steam is generated from water. Due to the active control system, the output

steam conditions are kept constant despite the varying heat output of the

plants excess heat.

This technique has the

capability of reducing drain water up to 10% of the original capacity,

resulting in 10 times the original discharge costs. The drainwater thickener is

capable of replacing active cooling devices such as ventilators or quenches, to

reduce the operational costs even further.