Heatpower

Fast responding thermal energy systems

SUPER CHARGED STEAM TURBINE SYSTEM FOR ELECTRICAL PEAK SHAVING

This project was funded with financial help of the European Union

VALUE PROPOSITION

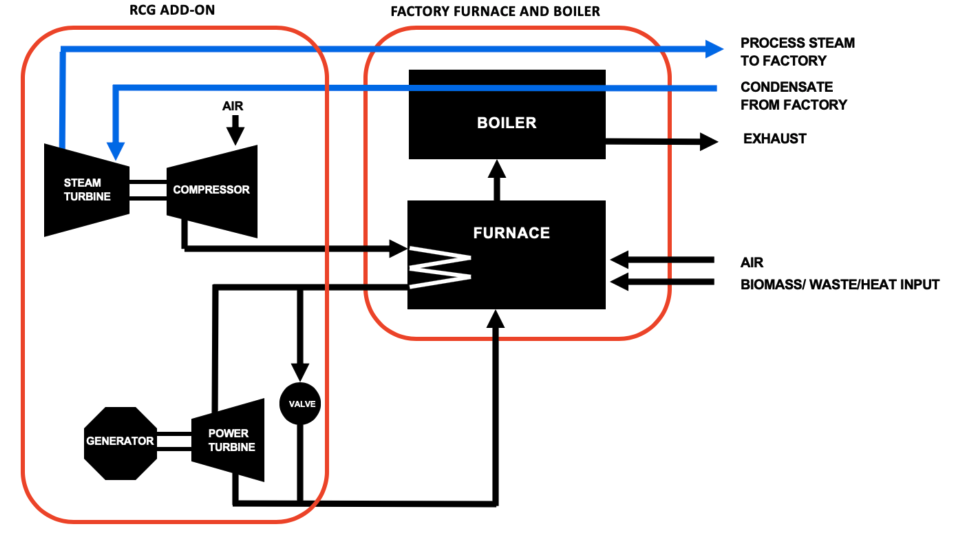

Heat Power B.V. developed the Rankine Compression Gas turbine (RCG), which is a supercharged steam turbine system for electrical peak shaving in steam and power intensive SMEs. The RCG principle boosts the power output of an oven fired steam cycle on average 10-25% and enables adjusting the electrical power output within seconds.

THE RCG OFFERS

• RAPID RESPONSE POWER

Response in seconds for electrical peak shaving

• 10–25 % POWER BOOST

Compared to conventional steam cycles

• CRUDE BIO & WASTE FUELS

Electrical power generating add-on to furnaces

TARGET MARKET

The RCG system is offered as an add-on system to existing boilers and can be connected to commercial furnaces firing crude biomass and waste fuels. The RCG add-on can be applied in small and medium (manufacturing) industries, such as food, wood, paper& pulp, thermal cleaning and others. The RCG is suitable for delivering electrical power in the range of 150kWe- 2MWe.

THE TECHNOLOGY

The novelty of the Rankine Compression Gas turbine (RCG) compared to existing steam cycles is, that the steam turbine drives the compressor of the gas turbine cycle. This means that this combined cycle installation is going to be able to operate at rapidly changing speeds, and give torque when the load is standing still. For a combined cycle, this is unique

Previous work

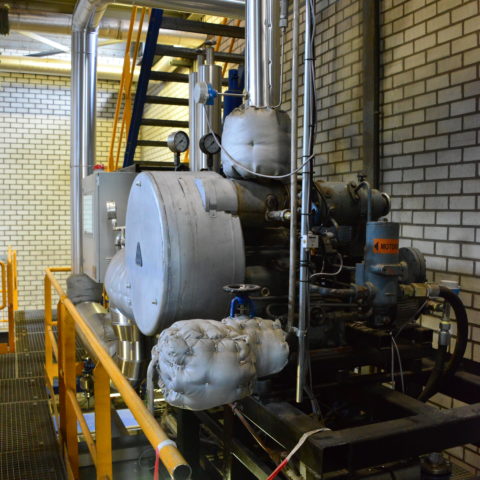

In September 2016 Heat Power received investment by EIT Innoenergy, who is currently shareholder in Heat Power. At the end of 2016 Heat Power B.V. secured funding from RVO (Dutch government) to demonstrate the RCG system as a small scale pilot at a wood processing plant near Eindhoven. This pilot was realized in fall 2017 (picture below). We are currently looking for partners to accelerate the business and realize the first RCG commercial power plant.

CURRENT STATUS

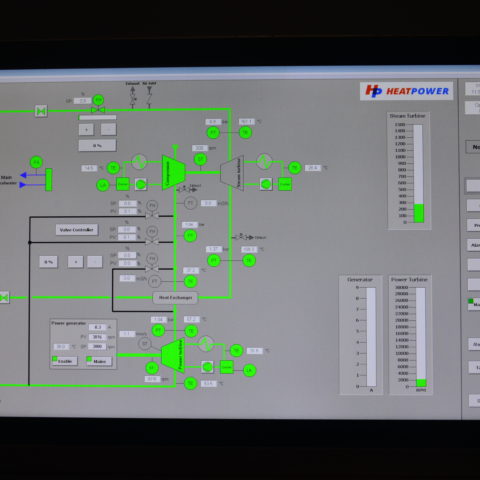

Heat Power B.V. has proven the technical feasibility of the RCG technology and tested a 5kWe prototype at Houtindustrie Schijndel (TRL-level 5, validation in industrial environment). Together with prefered assembly partner ACE from Lummen, a 40kWe prototype was developed . These 40kWe modules form the base for a parallel connected commercial modular designed system that can be developed designed for (base and peak) electricity demand up to 160kWe, 200kWe, 240kWe and beyond.